GLASS ASSEMBLY

From Simple to Complex Assemblies

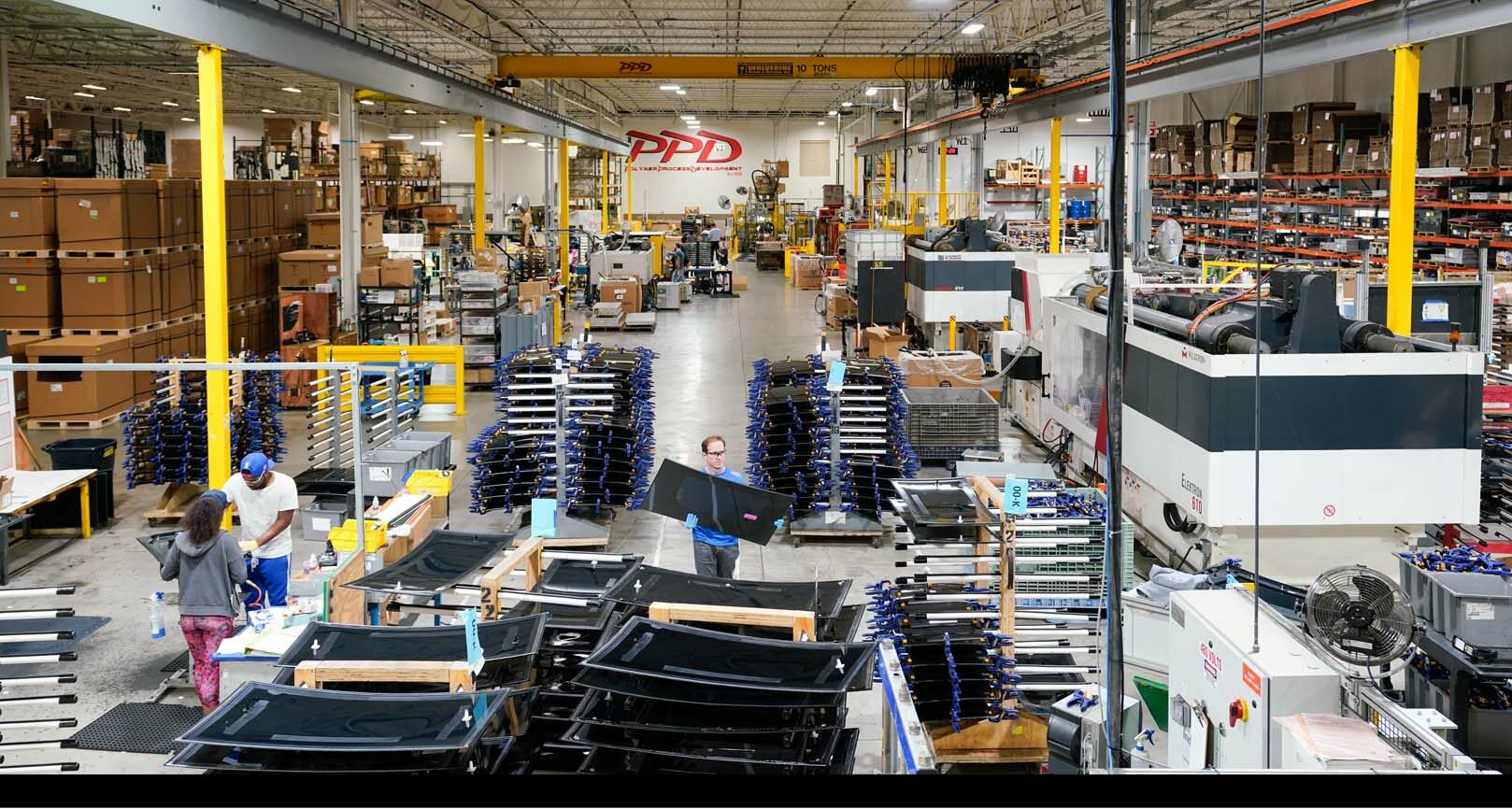

PPD utilizes a creative cross-functional team of engineers and technical support staff to develop everything from simple to complex glass assemblies. Simple can be, placing an automotive door glass clip in a specific location. Complex glass assemblies include proper location and application of rain sensors, brackets, and hinges. Other glass assembly operations include latest technologies in; camera vision, obstacle avoidance, lane departure, bonding brackets, soldering electrical leads, and application of extrusions.

These glass assembly systems are created using skilled production personnel and / or custom designed assembly equipment. A simplistic, streamlined approach offers quick start up of new programs, many times in days versus weeks or months.

Reliability of these systems come from replicating original equipment manufacturers (OEM) primers, adhesives, and materials. This elevates confidence in both short and long term performance. Materials include; single part urethanes, two part urethanes, RTV, hot melts, and cyanoacrylates.

We utilize a creative cross-functional team of engineers and technical support staff to develop everything from simple to complex assemblies