INJECTION MOLDING

PPD Provides Services In These Areas

Polymer Process Development isn’t just our name, it’s the very core of our business. Whether you provide your own tooling, or we construct it for you, we will apply our extensive knowledge and experience in injection molding to provide you with quality parts. After all, that’s what it’s all about.

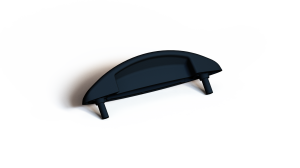

As part of our core competency, PPD is a very progressive, adaptive injection molder. We utilize only the latest technology to assure our products reflects the best value for all of our customers. Below is a short list of products to demonstrate just some our injection molding capabilities:

- Automotive Door Assembly Hardware

- Locating Clips

- Automotive Handles

- Wire guides

- Electrical Connectors

- Automotive Camera Holders

- AutomotiveVision System

- Containers/Specialty

Our injection molding capabilities include:

- 330 ton electric

- 610 ton electric

- 380 ton vertical (RIM and thermoplastic capable)

- (2) Walk-in clamp units (RIM and thermoplastic capable)

We can also support:

- Hydraulic Cores

- Hot Manifold

- Complete Process Monitoring (Temperature, Cavity Pressure, Part Presence, etc.)

Polymer Process Development isn’t just our name, it’s the very core of our business

PPD has been developing programs and encapsulating glass for over 20 years with a core group of dedicated seasoned professionals. Our engineering and manufacturing teams experience spans more than 70 years combined. We have completed engineering evaluations and reverse engineered over 1,500 unique products for many different industries. With this wide range of products and experience, we truly believe we have solutions to all of our customer’s needs.