SERVICES

Percent Faster Than

Our Closest Competitor

Our Closest Competitor

Percent Less Cost Than

Our Competition

Our Competition

Percent Customer Satisfaction

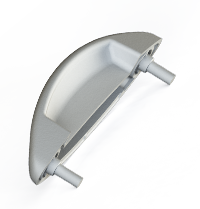

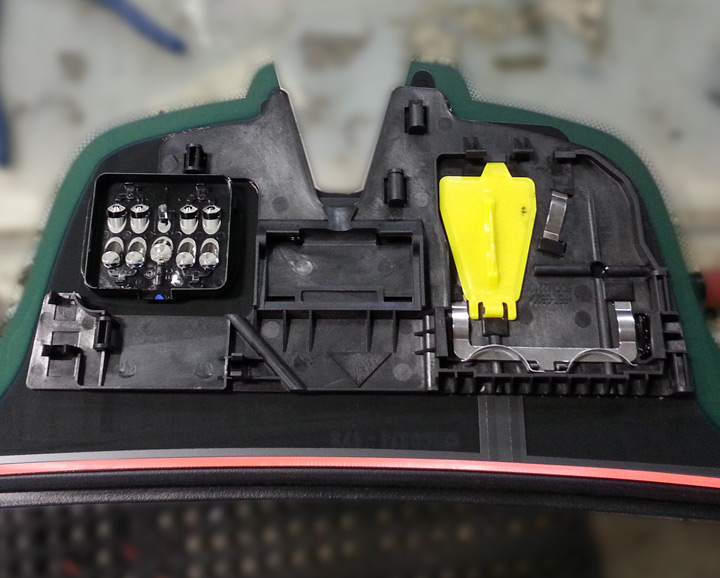

VALUE-ADD GLASS

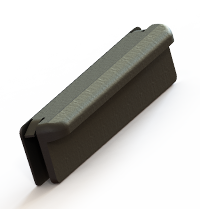

COMPONENT HARDWARE

PPD can not only design, mold, or print your part. We can also assemble or finish your components and products. PPD can snap, glue, bond, coat, paint, heat staking, or ultra-sonically weld your components for your finished assembly.

Learn More

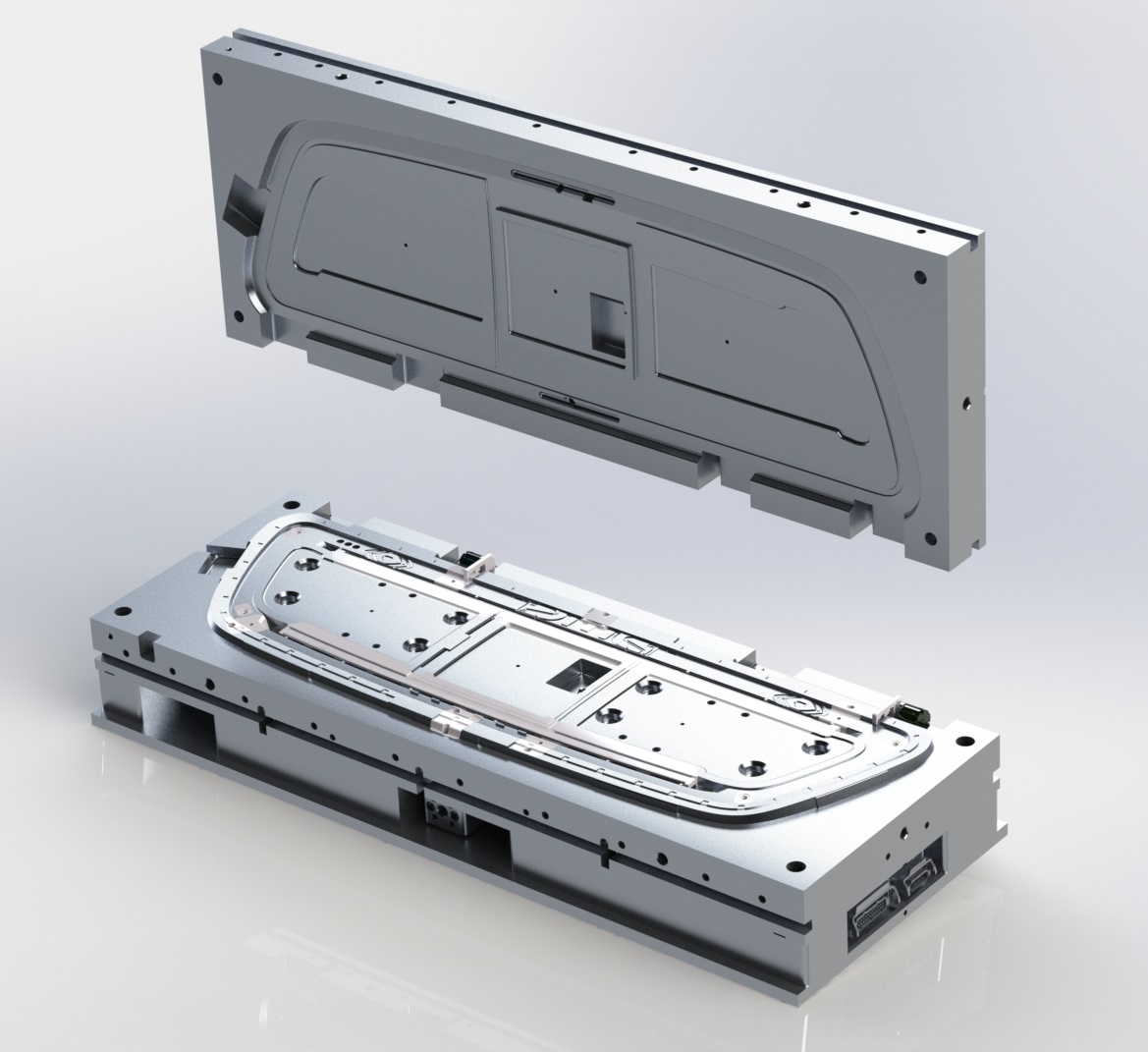

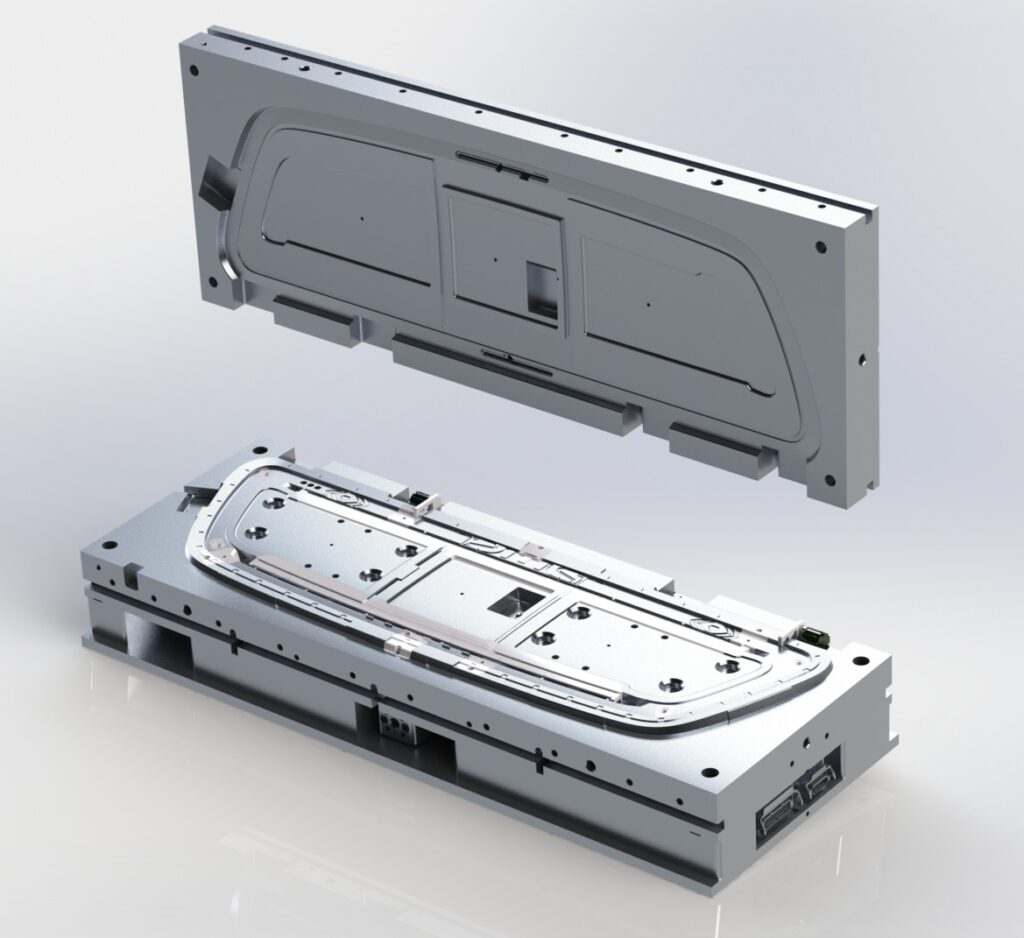

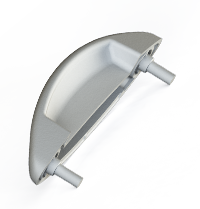

PLASTIC MOLDED COMPONENTS

Our injection molding technology is built around the focus on progressive designs and adaptability. We utilize only the latest technology to assure our products reflects the best value for all of our customers. Click here for a list of products to demonstrate some our capabilities.

PPD has been developing programs and encapsulating glass for over 20 years with a core group of dedicated seasoned professionals. Our engineering and manufacturing teams experience spans more than 70 years combined. We have completed engineering evaluations and reverse engineered over 1,500 unique products for many different industries. With this wide range of products and experience, we truly believe we have solutions to all of our customer’s needs.